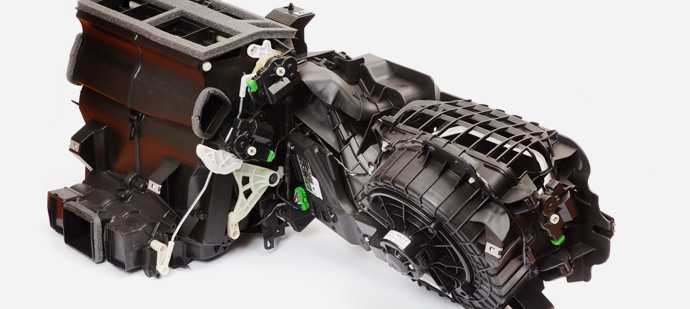

HVAC Module (Full Assembly)

As an expert in occupant comfort systems from concept through launch, Air International designs all subsytems: refrigerant, coolant loop, air-handling, electrical, control and software to integrate into any vehicle and meet any customer objective.

Air International delivers the highest value to its customers by integrating components we manufacture with the best choices of components from our world-class supplier partners. This business model allows us to offer high-value HVAC modules for any vehicle application. We design and test every module at the component, system and vehicle level so we can assure our customers they are receiving a completely integrated solution.

Air International makes console mounted units, overhead mounted units, or small auxiliary pusher systems. Air international also provides single, dual, tri, or quad zone systems to meet customer specifications. Air International can integrate its modules with other options such as automatic climate control, battery cooling and glove compartment cooling.

Each HVAC module has six primary components.

Evaporator

- Overall core size accounting for unique customer package

- Available coolant/liquid flow rate and other vehicle parameters

- Flow path style, number of passes, and tube type/geometry

- Fin height, pitch, density, louver angle

- Noise, vibration, and harshness considerations

- System purge, fill, and service procedures to be used

- Fittings constructed for ease of assembly and service

- Hydrophilic coating for improved water shedding, odor elimination and corrosion protection

- Nocolok Braze Aluminum construction

Heater Core

We design and manufacture heater cores to optimize performance by modeling multiple variables in a CAE/CFD environment.

- Overall core size accounting for unique customer package

- Available coolant/liquid flow rate and other vehicle parameters

- Flow path style, number of passes, and tube type/geometry

- Fin height, pitch, density, louver angle

- Noise, vibration, and harshness considerations

- System purge, fill, and service procedures to be used

- Fittings constructed for ease of assembly and service

- In-house optimized folded “B” manufacturing

- Nocolok Braze Aluminum construction

Blower Assembly

Air International partners with global suppliers to design and manufacture HVAC blower motor and impeller assemblies that offer our customers the best solution to meet their air flow and power consumption needs. Whether customers are looking for the efficiency of a brushless motor or the low cost of a brush-commutated motor, we have the expertise to deliver a quality part.

We also integrate the motor and impeller assembly selection with the development of the air-handling scroll. We use CAE and CFD tools to optimize airflow while ensuring the entire system meets the customer's noise and vibration specifications.

Actuators

We partner with our strategic suppliers to select the precise actuators to meet each customer's requirements and control architecture. Our actuator choices include feedback, pulse count, and step designs.

Air International engineers design kinematic systems using in-house tools that optimize cam profiles and linkages, giving our HVAC systems a high level of door travel accuracy and low noise.

Sensors

We use our supplier partners to provide sensors to monitor conditions such as in-car temperatures in one or more zones, sun load, and refrigerant pressures. Sensor data is processed by the control system we designed to actuate blowers, cooling fans, and compressor/clutch cycling.

Filters

Air International develops filtration designs that can capture dust and pollen particles of various sizes. Filtration specifications are integrated with flow optimization, noise vibration and harshness (NVH), and other design considerations, then sourced from one or more of our trusted supplier partners.